Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

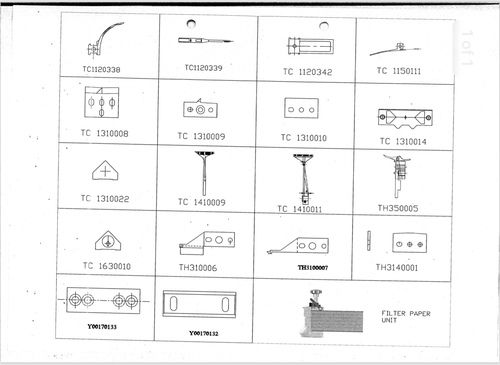

IMA C27 TH3500005 Needle Guide

Product Details:

- Drive Type Mechanical

- Noise Level Silent/No Noise

- Features Wear resistant, Corrosion resistant, Dimensional accuracy, Easy installation

- Usage & Applications Industrial

- Surface Finish Smooth, Coated

- Size Standard / Custom Fitting

- Shape Precision Channel Guide

- Click to View more

X

IMA C27 TH3500005 Needle Guide Price And Quantity

- 1 Piece

IMA C27 TH3500005 Needle Guide Product Specifications

- Mechanical

- 1 Year

- Coated

- Lightweight (Approx. as per part size)

- Silent/No Noise

- Alloy

- Wear resistant, Corrosion resistant, Dimensional accuracy, Easy installation

- Smooth, Coated

- Industrial

- Manual

- Standard / Custom Fitting

- Machine Spare Part

- Custom/Standard as per machine specification

- Metallic Grey

- Precision Channel Guide

- Precision Machining

IMA C27 TH3500005 Needle Guide Trade Information

- 100 Piece Per Month

- 30 Days

- standard

- Chandigarh, Sikkim, Manipur, Meghalaya, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, North India, East India, West India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Delhi, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Tamil Nadu, Telangana, Tripura, West Bengal, Gujarat, Kerala, Central India, Chhattisgarh, Himachal Pradesh, Uttar Pradesh, All India

Product Description

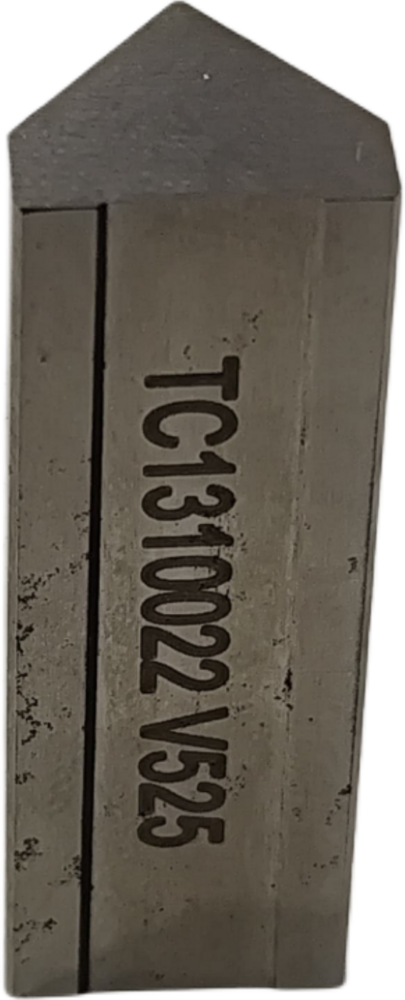

Needle Guide: Part No- Th3500005

IMA C27 /C27-E Spare Parts

The IMA C27-E offers high-output production of double chamberteabags without staples, incorporating envelope and cartoning capabilities.Our group company has been running this model for over a decade, enabling in-housetesting of all newly developed parts.

Vedika Machinery supplies a wide range of spares including:

- Envelope forming tools

- Heat sealing components

- Tag feeding and transfer systems

- Paper guiding and punching tools

- Roller assemblies and shafts

Precision Machining for Dimensional Accuracy

With advanced machining technology and strict tolerance of 0.01mm, the IMA C27 TH3500005 Needle Guide delivers exceptional dimensional stability, contributing to seamless integration and optimal performance. This precision ensures that the guide meets exact OEM standards for the IMA C27 Tea Bag Packaging Machine, reducing the likelihood of installation errors or operational inefficiencies.

Engineered for Endurance in Demanding Environments

Crafted from high-quality alloy with an advanced coated surface, this needle guide resists wear and corrosion even under high-speed, continuous-use conditions. Its robust construction and reliable performance make it suitable for industrial operations where longevity and minimal maintenance are critical to operational success.

FAQs of IMA C27 TH3500005 Needle Guide:

Q: How is the IMA C27 TH3500005 Needle Guide installed on the IMA C27 Tea Bag Packaging Machine?

A: Installation of the IMA C27 TH3500005 Needle Guide is straightforward, as it is designed as a direct fit replacement for the needle guide section of the IMA C27 Tea Bag Packaging Machine. Simply align the guide with the designated channel and secure it as per OEM instructions, ensuring precise integration and immediate operational readiness.Q: What is the primary function of the Needle Guide in the tea bag packaging process?

A: The Needle Guide supports and directs the needles movement within the packaging section, ensuring smooth, accurate operation during high-speed tea bag production. It minimizes noise, reduces friction, and maintains the structural alignment necessary for consistent, high-quality packaging outcomes.Q: When should the IMA C27 TH3500005 Needle Guide be replaced?

A: Replacement should occur according to the machines maintenance schedule or when signs of wear, diminished performance, or visible damage are detected. Ensuring timely replacement helps maintain operational efficiency and prevents downtime in industrial tea bag packaging processes.Q: Where is the needle guide located on the IMA C27 Tea Bag Packaging Machine?

A: The needle guide is specifically positioned in the needle guide section of the IMA C27 Tea Bag Packaging Machine. This placement is crucial for accurate needle tracking and proper tea bag formation during the packaging cycle.Q: What benefits does using a precision-machined, coated needle guide offer?

A: A precision-machined, coated needle guide ensures enhanced wear and corrosion resistance, dimensional accuracy, and silent performance. These features collectively extend the lifespan of the component, reduce maintenance needs, and improve overall machine reliability in demanding production environments.Q: How does the material and surface treatment contribute to the needle guides performance?

A: The alloy construction combined with a smooth, coated surface enhances durability and corrosion resistance, allowing the guide to function efficiently even under continuous, high-speed operation. These qualities are essential for sustaining operational integrity and reducing part replacements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free