Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

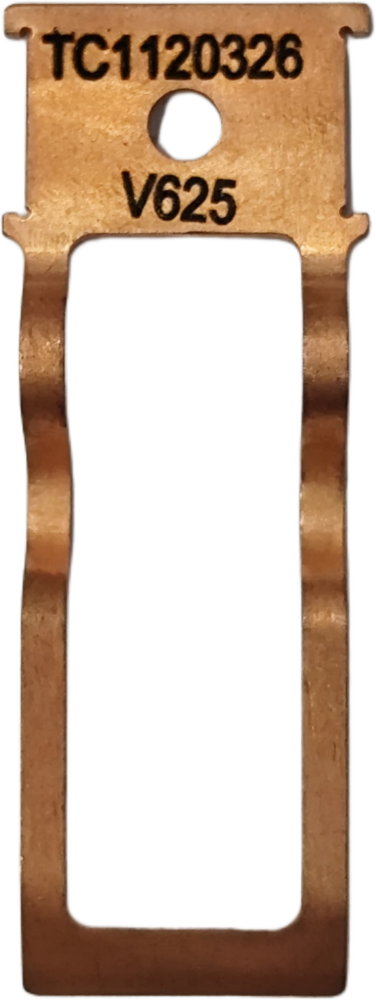

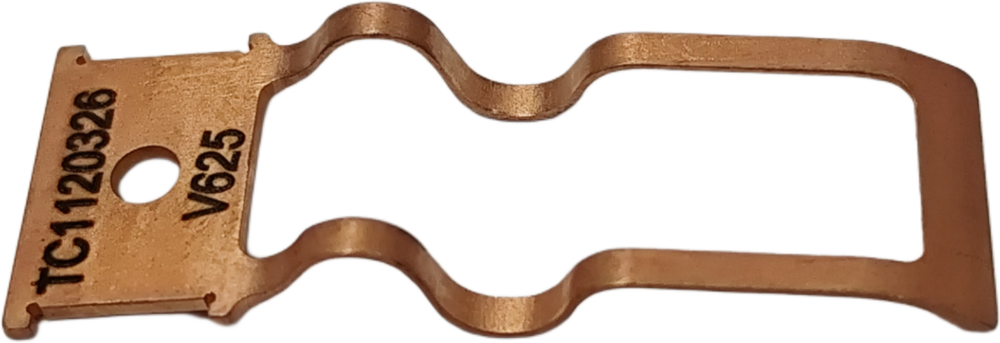

IMA C27 TC1120326 Gripper

Product Details:

- Capacity Consistent grip up to 20 cycles/min

- Lubricating System Manual Lubrication Required

- Usage & Applications Industrial

- Features Rust resistant, High grip precision, Easy installation

- Size Standard (per machine requirement)

- Shape Ergonomic

- Drive Type Mechanical

- Click to View more

X

IMA C27 TC1120326 Gripper Price And Quantity

- 1 Piece

IMA C27 TC1120326 Gripper Product Specifications

- Industrial

- Approx. 85mm x 38mm x 25mm

- Manual Lubrication Required

- Machine Spare Part

- Coated

- Standard Operating Pressure

- Mechanical

- Consistent grip up to 20 cycles/min

- 140 grams

- Smooth, Anti-corrosive

- Copper

- Precision Manufacturing

- Silent Operation

- Standard (per machine requirement)

- Alloy

- Mechanical

- Ergonomic

- Rust resistant, High grip precision, Easy installation

IMA C27 TC1120326 Gripper Trade Information

- 100 Piece Per Month

- 1 Months

Product Description

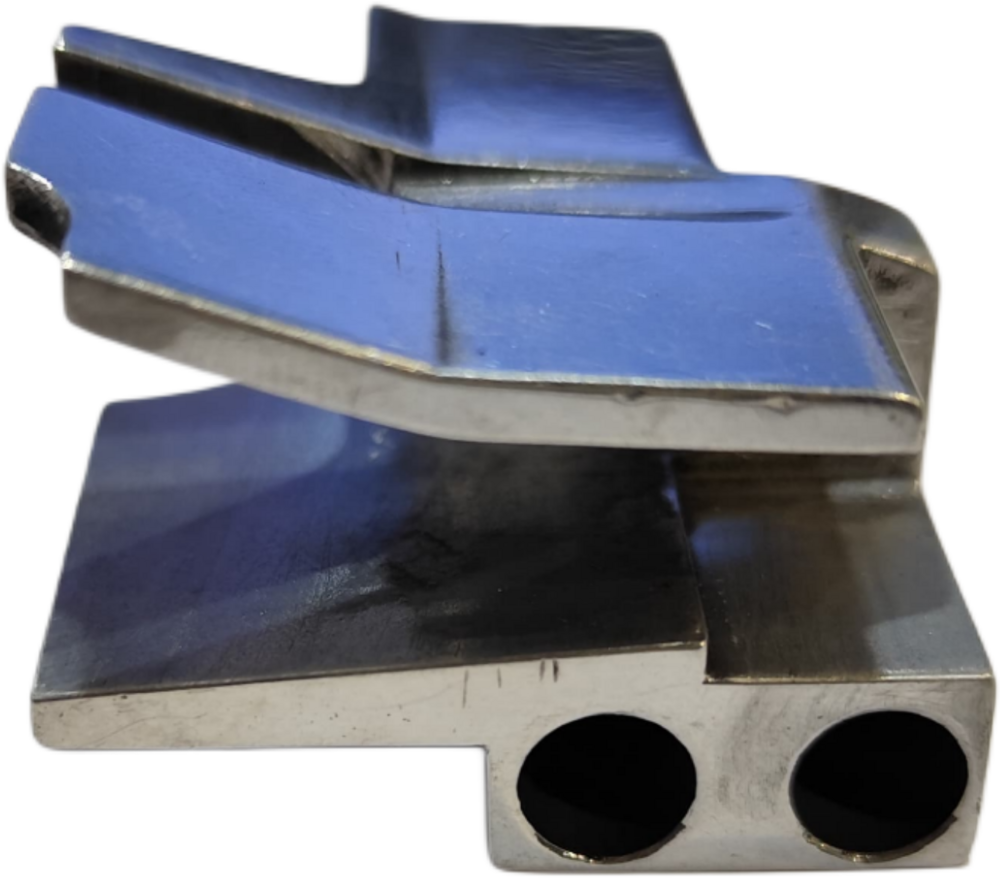

The Gripper (Part No. TC1120326) is a critical handling component in the IMA C27 teabag machine, responsible for securely gripping and transferring tags, threads, or filter paper during high-speed packaging cycles. It plays a key role in maintaining precise alignment and synchronization throughout the machines motion system. At Vedika Machinery, we manufacture the TC1120326 Gripper using high-strength, wear-resistant materials and advanced machining processes to ensure reliable performance and dimensional accuracy. Each unit is tested on running C27 machines to verify smooth operation and perfect fit. Our grippers deliver OEM-equivalent functionat up to 50% lower cost, supporting efficient maintenance.

Precision and Durability for Tea Bag Packaging

Crafted with advanced manufacturing techniques, the IMA C27 TC1120326 Gripper delivers precise and consistent grip performance on tea bag packaging lines. Its copper-coated, alloy structure offers enhanced rust resistance and longevity. Designed to withstand high temperatures up to 150C, the gripper is reliable even under challenging operating conditions, ensuring productivity and quality for industrial packaging environments.

Effortless Installation and Maintenance

This gripper features a plug-and-play direct fit for IMA C27 tea bag packaging machines, making installation hassle-free and efficient. Its manual lubrication requirement is straightforward, and overall maintenance needs are low. A recommended annual replacement schedule helps maintain peak effectiveness, supporting smooth and uninterrupted operations on the production floor.

FAQs of IMA C27 TC1120326 Gripper:

Q: How do I install the IMA C27 TC1120326 Gripper on my tea bag packaging machine?

A: The IMA C27 TC1120326 Gripper is designed as a direct-fit, plug-and-play component for IMA C27 tea bag packaging machines. Simply replace the existing gripper by aligning the new part according to the machines requirements and secure it in place as per your manufacturers guidelines.Q: What are the key benefits of using this gripper in industrial packaging?

A: This gripper offers high grip precision, consistent performance up to 20 cycles per minute, and heat resistance up to 150C. Its anti-corrosive, rust-resistant alloy construction and silent operation make it a dependable and durable choice for continuous industrial use.Q: When should I replace the IMA C27 TC1120326 Gripper?

A: It is recommended to replace the gripper every 12 months to ensure optimal performance and prevent any potential disruption in the packaging process.Q: Where is the IMA C27 TC1120326 Gripper manufactured and exported from?

A: This gripper is manufactured and exported from India, ensuring global quality standards and availability for international customers.Q: What maintenance does the gripper require for long-lasting use?

A: The gripper needs only minimal maintenance, primarily manual lubrication, to keep its moving parts operating smoothly. Regular maintenance helps prolong its lifespan and maintains peak performance.Q: How does the anti-corrosive surface treatment benefit my packaging process?

A: The coated, anti-corrosive surface finish protects the gripper from rust and wear, which is particularly advantageous in humid or high-temperature environments, thereby ensuring the reliability and longevity of your packaging machinery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS