Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

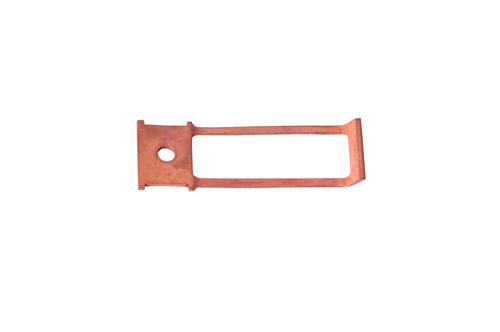

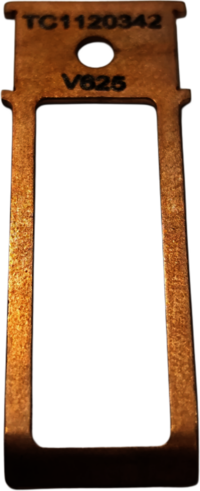

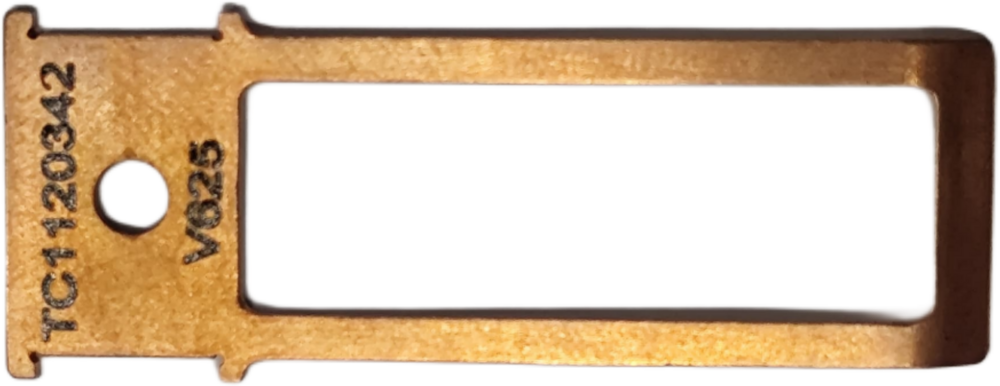

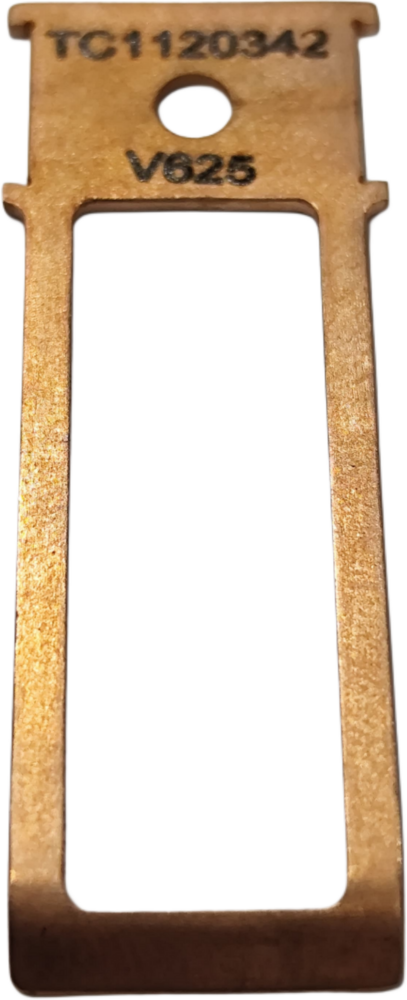

IMA C27 TC1120342 Gripper

Product Details:

- Usage & Applications Industrial

- Product Type Machine Spare Part

- Material Alloy

- Surface Treatment Coated

- Color Copper

- Warranty 1 Year

- Click to View more

IMA C27 TC1120342 Gripper Price And Quantity

- 1 Piece

IMA C27 TC1120342 Gripper Product Specifications

- 1 Year

- Machine Spare Part

- Alloy

- Coated

- Industrial

- Copper

IMA C27 TC1120342 Gripper Trade Information

- 100 Piece Per Month

- 1 Months

Product Description

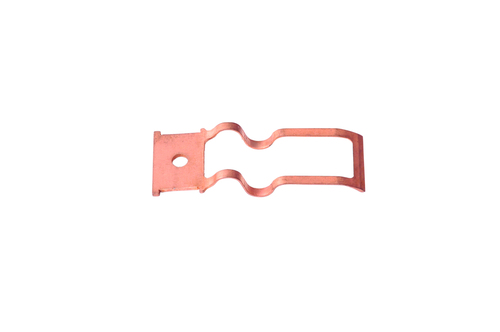

The Gripper (Part No. TC1120342) is a vital component in the IMA C27 teabag machine, designed to grip and transport materials such as thread, tag, or filter paper with precision during the packaging cycle. It plays a key role in maintaining accurate positioning and ensuring smooth, synchronized motion across high-speed operations. At Vedika Machinery, we manufacture the TC1120342 Gripper using high-strength, wear-resistant materials, precision-machined to match OEM dimensions. Each unit is tested on active C27 machines to verify consistent grip, fit, and long-term performance. Our grippers deliver OEM-grade reliabilityat up to 50% lower cost, maximizing value and efficiency.

Premium Alloy Construction

Built from a superior-grade alloy, the IMA C27 TC1120342 Gripper delivers excellent strength and durability. Its robust design ensures stability and longevity, making it highly reliable for demanding industrial applications. The copper surface finish not only adds to its aesthetic appeal but also boosts its resistance to corrosion, extending its operational lifespan.

Designed for Industrial Excellence

Purpose-engineered for industrial usage, this gripper streamlines material handling processes, offering a firm and secure grip on a range of components. Its versatile design makes it a optimal fit for automated assembly lines and material transfer systems, facilitating smoother and safer operations in manufacturing facilities.

Assurance and Quality Backed by Warranty

Each IMA C27 TC1120342 Gripper is covered by a comprehensive 1-year warranty, underscoring its reliable performance and quality standards. The warranty assures users of repair or replacement for eligible defects, offering peace of mind to industrial operators and purchasers.

FAQs of IMA C27 TC1120342 Gripper:

Q: How is the IMA C27 TC1120342 Gripper typically used in industrial settings?

A: The IMA C27 TC1120342 Gripper is employed in automated and manual material handling within factories. It securely grips and transfers components or workpieces, enhancing production efficiency in assembly lines and other automated systems.Q: What materials and surface treatments are used in the construction of this gripper?

A: This gripper is manufactured from high-strength alloy and features a copper coloration with a coated surface treatment. The coating significantly improves its resistance to wear and corrosion in rigorous industrial environments.Q: When should I consider replacing the gripper in my production process?

A: Replacement is recommended if the gripper shows signs of significant wear, loss of grip precision, or physical damage. Regular inspection during the one-year warranty period can help detect early signs of issues.Q: Where is the IMA C27 TC1120342 Gripper manufactured, and can it be exported?

A: The gripper is produced in India by an experienced manufacturer and is available for export, meeting the requirements of international industrial clients.Q: What is the process for warranty claims on this gripper?

A: In case of defects covered under the 1-year warranty, users should contact the manufacturers service team with purchase details and issue description. The gripper will be inspected, and repairs or replacement will be provided as per warranty conditions.Q: How does the grippers coated copper finish benefit my operations?

A: The coated copper surface provides enhanced protection against rust and corrosion, extending the grippers service life and ensuring consistent performance, even in challenging industrial conditions.Q: What advantages does the IMA C27 TC1120342 Gripper offer to manufacturers and exporters?

A: Manufacturers and exporters benefit from its reliable performance, durable design, and ease of integration into various industrial applications, making it a cost-effective choice for both domestic and international markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free