Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

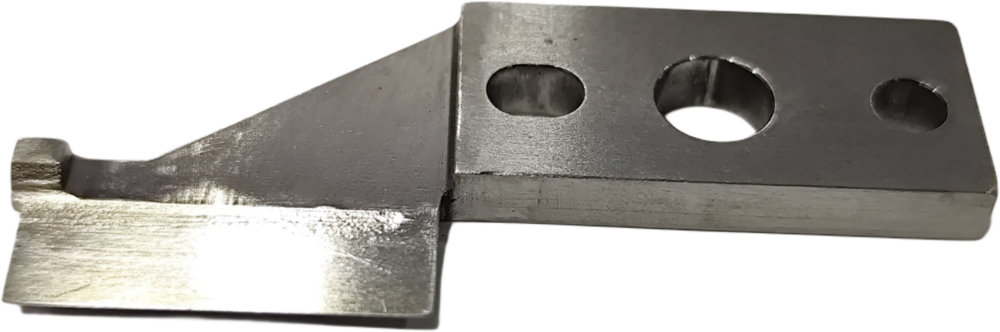

IMA C24 TH3100006 Bottom shaper of the package rear lower

100 आईएनआर/टुकड़ा

उत्पाद विवरण:

- उपयोग/अनुप्रयोग Industrial

- साइज Customized

- प्रॉडक्ट टाइप

- मटेरियल Alloy

- टेक्नोलॉजी

- सतह का उपचार

- रंग Gray

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 100

उत्पाद की विशेषताएं

- Industrial

- Customized

- Alloy

- Gray

उत्पाद वर्णन

The Bottom Shaper Rear Lower (Part No. TH3100006) is a vital forming tool in the IMA C24 teabag packaging machine, designed to shape the bottom rear portion of the envelope with high accuracy. It plays a crucial role in creating a consistent and professionally finished teabag pouch during high-speed operations. At Vedika Machinery, we produce the TH3100006 Bottom Shaper using precision CNC-machining and high-strength alloys to ensure exact fit, stability, and wear resistance. Each unit is trial-fitted on running C24 machines. Our bottom shapers deliver consistent OEM-level performance at up to 50% reduced cost for economical, reliable maintenance.

Precision Engineering with CNC Technology

Our bottom shaper utilizes state-of-the-art CNC technology, ensuring accurate dimensions and seamless compatibility in industrial applications. This technological edge guarantees every unit meets rigorous quality standards and delivers consistent results.

Superior Material & Surface Protection

Constructed from high-quality alloy and finished with a protective coating, the IMA C24 TH3100006 bottom shaper offers enhanced resistance to corrosion and mechanical stress. This combination lengthens product lifespan and minimizes maintenance needs.

Tailored for Industrial Applications

With customizable size options and its durable gray finish, this bottom shaper is designed to meet diverse industrial demands. Whether upgrading existing infrastructure or building new machinery, it provides the reliability and adaptability manufacturers require.

FAQs of IMA C24 TH3100006 Bottom shaper of the package rear lower:

Q: How is the IMA C24 TH3100006 bottom shaper manufactured?

A: The bottom shaper is manufactured using advanced CNC (Computer Numerical Control) technology, which allows for precise shaping and consistent quality. Alloy material is carefully machined, then coated to enhance durability before final quality checks and shipment.Q: What are the main benefits of using this bottom shaper in industrial settings?

A: This bottom shaper offers excellent wear resistance due to its alloy construction and coated surface. Its customized sizing ensures seamless integration with your packaging machinery, enhancing operational efficiency and reducing downtime for maintenance.Q: When should I consider replacing or upgrading the bottom shaper in my machinery?

A: Its recommended to replace the bottom shaper if you notice decreased performance, visible wear, or frequent malfunctions in the package rear lower section. Upgrading to this customized, CNC-machined part ensures optimal machinery function and longevity.Q: Where is the IMA C24 TH3100006 bottom shaper primarily used?

A: The bottom shaper is primarily used in industrial packaging applications, specifically for the package rear lower section of machinery. It is ideal for manufacturing plants and export operations that require reliable and durable machine components.Q: What is the surface treatment applied to the bottom shaper?

A: The IMA C24 TH3100006 bottom shaper features a coated surface, which provides additional protection against corrosion, friction, and environmental wear, ensuring extended service life even under challenging industrial conditions.Q: How can customizing the size of this bottom shaper benefit my application?

A: Custom sizing allows the bottom shaper to fit perfectly into your existing machinery setup, minimizing installation effort and ensuring optimal mechanical performance. This tailored approach improves operational efficiency and machine reliability.Q: What process is followed to ensure quality in manufacturing this shaper?

A: The manufacturing process involves selecting high-quality alloy, precision machining it with CNC technology, applying a protective coating, and conducting thorough inspections to meet industrial quality standards before delivery.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Send Email

Send Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें