Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

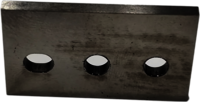

IMA C27 TC1310010 Blade (Counteracting)

उत्पाद विवरण:

- उपयोग/अनुप्रयोग Industrial

- साइज Customized

- प्रॉडक्ट टाइप

- मटेरियल Alloy Steel

- टेक्नोलॉजी

- सतह का उपचार

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- आईएनआर

- 100

उत्पाद की विशेषताएं

- Customized

- Industrial

- Alloy Steel

उत्पाद वर्णन

The Counteracting Blade (Part No. TC1310010) is a key cutting component in the IMA C27 teabag packaging machine. It functions as the fixed or supporting blade in conjunction with a moving knife, enabling clean and precise cuts of filter paper, thread, or tag materials during high-speed operation. At Vedika Machinery, we manufacture the TC1310010 Blade using high-hardness tool steel, engineered for durability, sharpness retention, and minimal wear. Each blade is tested on operational C27 units to ensure perfect alignment and smooth cutting performance. Our blades provide OEM-equivalent cutting efficiency at up to 50% lower cost, making them a cost-effective maintenance solution.Precision Manufacturing for Superior Performance

IMA C27 TC1310010 Blades are manufactured utilizing high-grade alloy steel and advanced CNC technology. This ensures precision, strength, and longevity, meeting the rigorous demands of industrial users. Each blade undergoes stringent quality control to guarantee optimal performance in a variety of applications.

Customized Solutions for Industrial Applications

We offer customized sizing for the IMA C27 TC1310010 Blade, tailored to fit your specific industrial requirements. Our blades are surface-treated with a specialized coating, providing enhanced resistance to corrosion and extending operational life. This adaptability makes our solutions ideal for diverse industrial sectors.

FAQs of IMA C27 TC1310010 Blade (Counteracting):

Q: How is the IMA C27 TC1310010 Blade manufactured?

A: The IMA C27 TC1310010 Blade is produced using advanced CNC technology from high-quality alloy steel, ensuring precise dimensions and consistent performance. The blade is then coated to improve surface hardness and resistance to environmental factors.Q: What are the primary industrial applications for this blade?

A: This blade is designed for use in various industrial sectors where cutting, trimming, or shaping of materials is required. Its robust construction and coated surface make it suitable for heavy-duty, continuous operations.Q: When should I consider replacing the IMA C27 TC1310010 Blade?

A: Replacement is recommended when you observe signs of wear such as reduced cutting efficiency, visible chipping, or deformation. Regular maintenance checks can help determine the optimal replacement interval based on your applications intensity.Q: Where can I order customized IMA C27 TC1310010 Blades from India?

A: You can place orders directly with us, as we are a leading exporter and manufacturer of these blades based in India. Our team assists in customizing sizes and specifications to match your project requirements.Q: What surface treatment is applied to the blade and what are its benefits?

A: The blade receives a specialized coating during manufacturing. This treatment increases its resistance to abrasion and corrosion, thereby extending the overall service life of the blade.Q: How does utilizing CNC technology benefit the blades performance?

A: CNC technology ensures unmatched dimensional accuracy and repeatable quality across every batch. This results in blades that deliver enhanced precision, efficiency, and reliability in industrial applications.Q: What advantages does alloy steel provide for the IMA blade?

A: Alloy steel imparts superior strength and durability to the blade, making it less prone to cracking and breaking under intensive industrial use. This helps maintain consistent cutting performance over time.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Send Email

Send Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें