Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

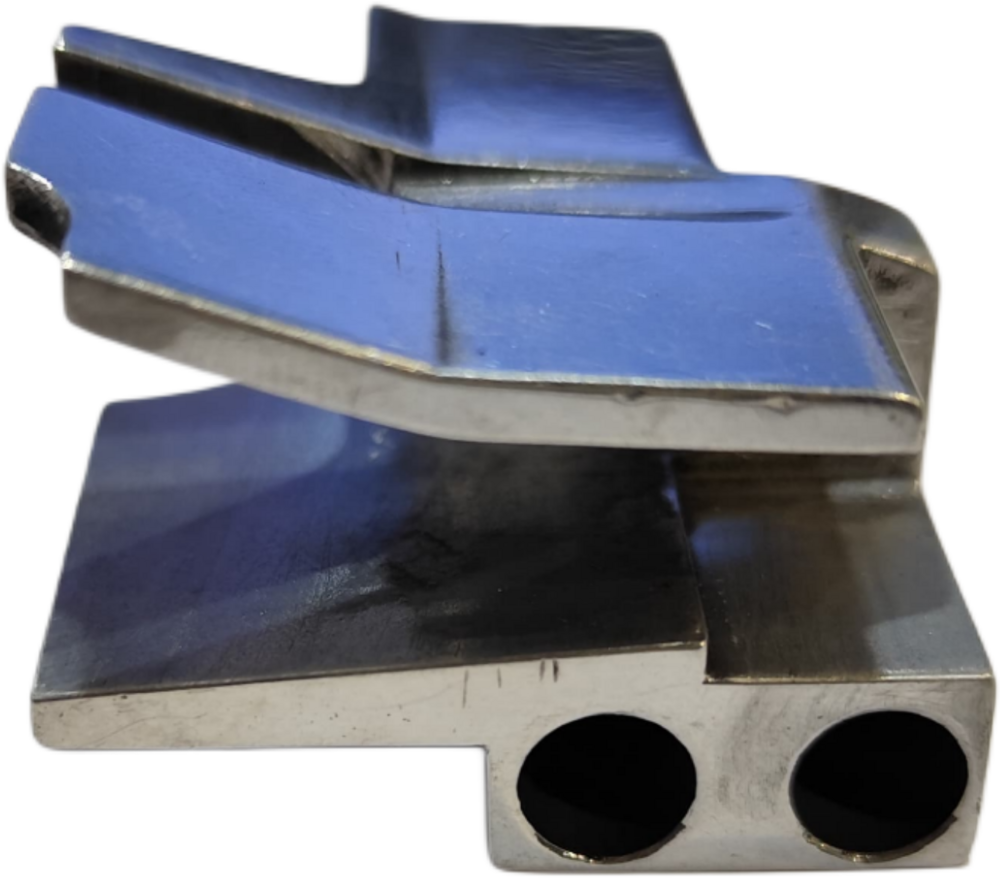

IMA C27 Needle

Product Details:

- Usage & Applications Industrial

- Product Type Machine Spare Part

- Material Alloy

- Surface Treatment Coated

- Color Gray

- Warranty 1 Year

- Click to View more

IMA C27 Needle Price And Quantity

- 1 INR/Piece

- 1 Piece

- 100.00 - 100.00 INR/Piece

IMA C27 Needle Product Specifications

- 1 Year

- Coated

- Alloy

- Machine Spare Part

- Gray

- Industrial

IMA C27 Needle Trade Information

- 100 Piece Per Month

- 1 Months

Product Description

The offered Needle is outlined in the similar structure of a sewing machine needle. However, it is a heavy-duty machine component and is mainly used to sew the fibers, fabrics and other materials in machines. This is created from toughest metal in small and round structure that has a small section that holds the thread in an ideal manner. Our Needle has a tough handle that has two flat sections, which enable it to be attached and installed easily into the needle holder.

The IMA C27-E offers high-output production of double chamber teabags without staples, incorporating envelope and cartoning capabilities. Our group company has been running this model for over a decade, enabling in-house testing of all newly developed parts.

Vedika Machinery supplies a wide range of spares including:

Envelope forming tools

Heat sealing components

Tag feeding and transfer systems

Paper guiding and punching tools

Roller assemblies and shafts

Each part is manufactured using cutting-edge machining and reverse-engineered from active machines.

Engineered for Industrial Environments

The IMA C27 Needle is specifically crafted to withstand challenging industrial operations. Its alloy material paired with a coated surface treatment enhances resistance against wear, contributing to a prolonged service life even under strenuous usage.

Trusted Manufacturer and Exporter in India

IMA is recognized as a leading manufacturer and exporter of industrial needles from India. Their adherence to strict quality standards ensures that the C27 Needle meets global demands for precision, reliability, and superior material quality.

FAQ's of IMA C27 Needle:

Q: How should the IMA C27 Needle be used in industrial applications?

A: The IMA C27 Needle is designed for insertion into compatible industrial machinery. Ensure proper alignment during installation and follow equipment manuals to guarantee optimum performance and safety during operation.Q: What are the key benefits of the coated, alloy construction of the IMA C27 Needle?

A: The coated alloy construction enhances the needle's durability, resists corrosion, and provides superior wear resistance. This leads to reduced maintenance, fewer machine downtimes, and a longer overall lifespan for the needle.Q: When is it recommended to replace the IMA C27 Needle?

A: It is advisable to inspect the needle periodically and replace it if any signs of wear, bending, or reduction in performance are observed. Replacement frequency depends on operational intensity, but yearly replacement is supported by the product's 1-year warranty.Q: Where can the IMA C27 Needle be sourced for industrial use?

A: This needle can be obtained directly from IMA, a reputable manufacturer and exporter based in India. Orders can typically be placed via their authorized distributors or directly through their official channels for global shipping.Q: What process is used to ensure the needle's surface durability?

A: A specialized coating process is applied to the alloy material, enhancing the surface's resistance to abrasion, corrosion, and environmental factors, which is essential for industrial-grade performance.Q: How does the 1-year warranty benefit users of the IMA C27 Needle?

A: The 1-year warranty provides assurance of quality and reliability, offering support for replacement or repair should manufacturing defects arise within the warranty period, thus minimizing operational risks.Q: What types of industrial applications are suitable for the IMA C27 Needle?

A: The IMA C27 Needle is well-suited for various heavy-duty industrial processes that require precision and resilience, including but not limited to textile manufacturing, machinery maintenance, or material assembly operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free