Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

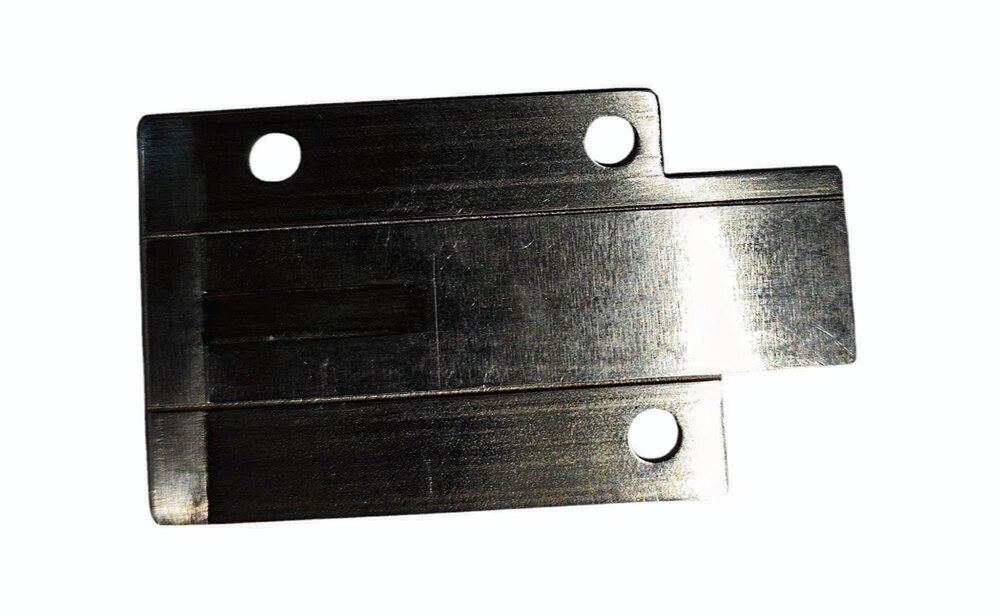

IMA C21 Heat Sealing Jaw

Product Details:

- Usage & Applications Industrial

- Product Type Machine Spare Part

- Material Alloy

- Surface Treatment Coated

- Color Gray

- Warranty 1 Year

- Click to View more

X

IMA C21 Heat Sealing Jaw Price And Quantity

- 1 Set

IMA C21 Heat Sealing Jaw Product Specifications

- 1 Year

- Machine Spare Part

- Gray

- Alloy

- Coated

- Industrial

IMA C21 Heat Sealing Jaw Trade Information

- 100 Set Per Month

- 1 Months

Product Description

IMA C21 SpareParts

The IMA C21 is a high-speed machine for the production of doublechamber string & tag teabags sealed with staples. It has remained atrusted solution for decades due to its reliability and mechanical simplicity.

At Vedika Machinery, we have over 30 years of hands-onoperational experience with the C21, and supply a comprehensive range ofprecision spare parts reverse engineered to meet or exceed OEM specifications.

We supply spare parts for:

- Cutting systems

- Knives and punches

- Tag transport and clamping

- Envelope mechanisms

- Thread feeding and staple modules

- Motion transmission elements (gears, cams, shafts)

Each part is manufactured using high-grade imported materials andtested for fit, finish, and durability on running C21 machines..

Durable Design for Industrial Performance

Built with high-quality alloy and finished with a protective coated surface, the IMA C21 Heat Sealing Jaw stands up to rigorous industrial use. Its gray profile not only offers an appealing appearance but also signals the jaw's resilience against wear, ensuring longevity and dependability during continuous operations.

Versatile Applications Across Industries

As a staple in industrial environments, the C21 Heat Sealing Jaw efficiently seals a variety of materials. Exported and manufactured in India, this versatile tool is chosen by businesses worldwide, thanks to its adaptability and suitability for diverse heat sealing processes.

FAQ's of IMA C21 Heat Sealing Jaw:

Q: How is the IMA C21 Heat Sealing Jaw used in industrial applications?

A: The IMA C21 Heat Sealing Jaw is typically installed in industrial heat sealing machines, where it is used to apply heat and pressure to seal different materials securely. Its alloy construction ensures consistent sealing results, making it ideal for production environments requiring reliability and efficiency.Q: What materials compose the IMA C21 Heat Sealing Jaw?

A: This heat sealing jaw is crafted from a durable alloy and features a coated surface treatment. These materials provide added strength, corrosion resistance, and a prolonged operational lifespan, making it suitable for heavy-duty industrial work.Q: When should the IMA C21 Heat Sealing Jaw be replaced or serviced?

A: Regular inspection is recommended, but with its robust alloy construction and coated surface, the jaw is designed for extended use. It generally requires replacement or servicing when you notice a decline in sealing quality or visible wear, which is often well beyond the one-year warranty period under normal use.Q: Where is the IMA C21 Heat Sealing Jaw manufactured and exported from?

A: The IMA C21 Heat Sealing Jaw is manufactured and exported by a reputable exporter and manufacturer based in India, serving industrial customers worldwide.Q: What is the process for installing the IMA C21 Heat Sealing Jaw?

A: Installation is straightforward: the jaw is mounted onto compatible heat sealing machines, following the manufacturer's guidelines. Proper alignment and secure fitting are essential to ensure optimal performance and consistent heat sealing results.Q: What are the primary benefits of choosing the IMA C21 Heat Sealing Jaw?

A: Key benefits include its durability from the alloy material, added protection from the coating, reliable performance, and compatibility with a range of industrial applications. Additionally, the one-year warranty offers assurance of quality and support.Q: How does the coated surface treatment enhance the performance of the IMA C21 Heat Sealing Jaw?

A: The coated surface provides a protective layer that helps resist corrosion and wear, maintaining a smooth sealing interface and extending the jaw's usability in demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free