Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

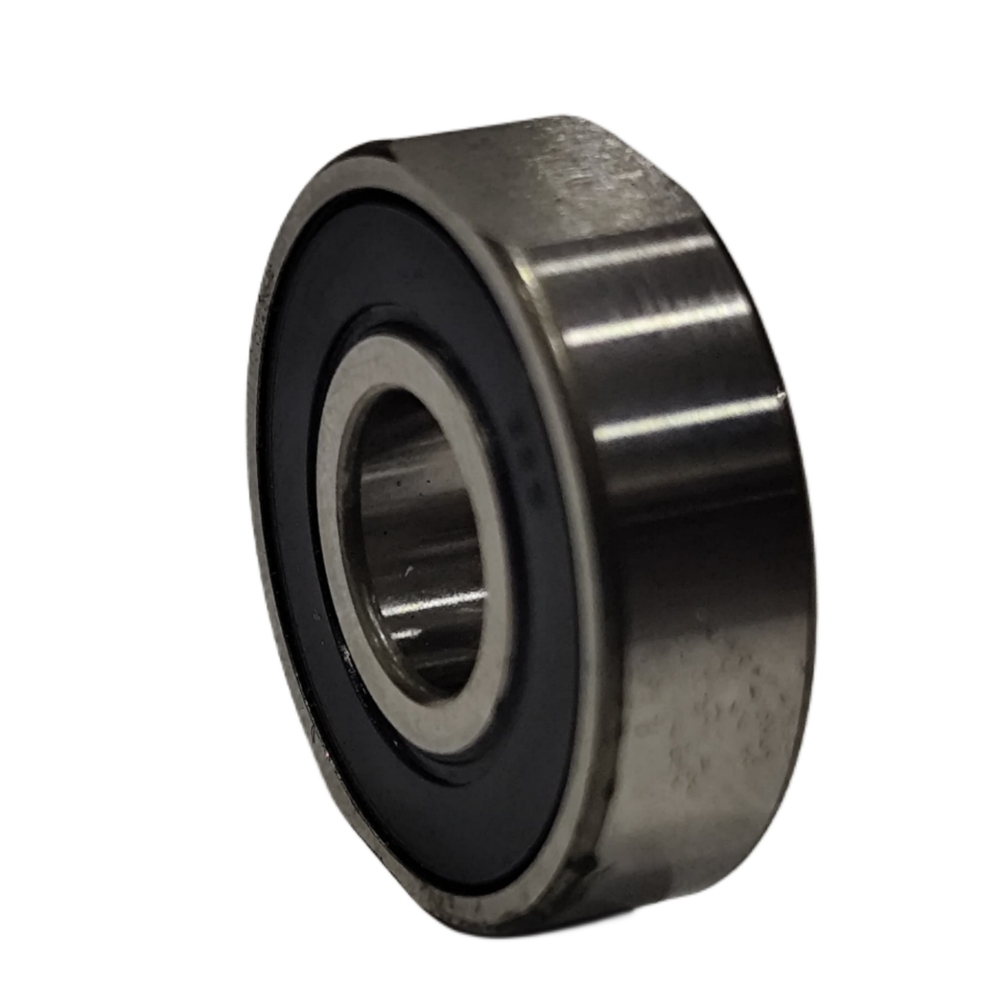

Constanta 727 Bearing

उत्पाद विवरण:

- साइज Customized

- उपयोग/अनुप्रयोग Industrial

- प्रॉडक्ट टाइप

- मटेरियल Alloy

- टेक्नोलॉजी

- सतह का उपचार

- रंग Gray

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- आईएनआर

- 100

उत्पाद की विशेषताएं

- Gray

- Customized

- Industrial

- Alloy

उत्पाद वर्णन

The Bearing (Part No. 727) is a precision-engineered rotational support component used in Constanta teabag packing machines, designed to reduce friction and support smooth, stable movement of shafts and rotating elements. It plays a critical role in ensuring accurate alignment, reducing wear, and enhancing overall machine performance.

Manufactured from high-quality, wear-resistant materials, the 727 Bearing is built to perform reliably under continuous, high-speed packaging conditions. Engineered to exact OEM specifications, it provides a precise fit, easy installation, and long service life.

This bearing is essential for maintaining efficient, low-maintenance operation in demanding tea packaging environments.

Advanced Surface Treatment for Longevity

Each Constanta 727 Bearing undergoes a coated surface treatment, adding a protective layer that significantly improves resistance to wear, corrosion, and harsh environmental factors. This enhancement ensures the bearing delivers prolonged service life with reduced maintenance requirements, making it a dependable choice for industrial machinery operating in challenging settings.

Precision Engineering with CNC Technology

Utilizing cutting-edge CNC technology, Constanta manufactures bearings that meet strict tolerances and high-quality standards. This process guarantees uniformity, optimal performance, and reliability across all units, regardless of customized size. Customers benefit from precise fits and dependable operation, vital for efficient machinery performance.

FAQs of Constanta 727 Bearing:

Q: How is the Constanta 727 Bearing manufactured to ensure quality?

A: The Constanta 727 Bearing is produced using advanced CNC technology, which enables precise engineering and maintains strict quality controls throughout the manufacturing process. This ensures dimensional accuracy and consistency across each bearing, regardless of customization.Q: What is the main benefit of the coated surface treatment on this bearing?

A: The coated surface treatment provides superior resistance to corrosion and wear, extending the bearings operational life even in harsh industrial environments. This protective layer reduces maintenance needs and enhances the overall durability of the bearing.Q: When should you consider using the Constanta 727 Bearing in industrial machinery?

A: You should opt for the Constanta 727 Bearing when you require reliable performance, exceptional durability, and resistance to challenging environmental conditions. Its customized size options make it suitable for a wide variety of machinery setups.Q: Where are Constanta 727 Bearings typically used?

A: These bearings are primarily used in industrial applications, including manufacturing plants, processing units, and heavy machinery. Their robust design makes them well-suited for operations that demand long-lasting and efficient rotational support.Q: What is the process for customizing the size of this bearing?

A: Clients can specify their required dimensions and operational parameters when placing an order. Constantas engineering team utilizes CNC technology to precisely manufacture bearings that meet these unique requirements, ensuring optimal fit and functionality.Q: How does the bearings alloy material contribute to its performance?

A: The alloy material provides a strong yet lightweight structure, which enhances load-bearing capacity and reduces the risk of deformation under pressure. This material choice supports both durability and efficient operation in industrial usage.Q: What are the export capabilities of Constanta for the 727 Bearing?

A: As a leading manufacturer and exporter in India, Constanta delivers the 727 Bearing to clients worldwide, ensuring compliance with international standards and offering reliable support for businesses seeking high-quality industrial bearings.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Send Email

Send Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें