Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

Constanta 1666 Bushing

100 आईएनआर/टुकड़ा

उत्पाद विवरण:

- उपयोग/अनुप्रयोग Packaging machinery Part

- सतह की फ़िनिश Polished

- साइज Customized

- प्रॉडक्ट टाइप

- मटेरियल Alloy Steel

- सतह का उपचार

- रंग Silver, Black

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 100

उत्पाद की विशेषताएं

- Polished

- Alloy Steel

- Packaging machinery Part

- Silver, Black

- Customized

उत्पाद वर्णन

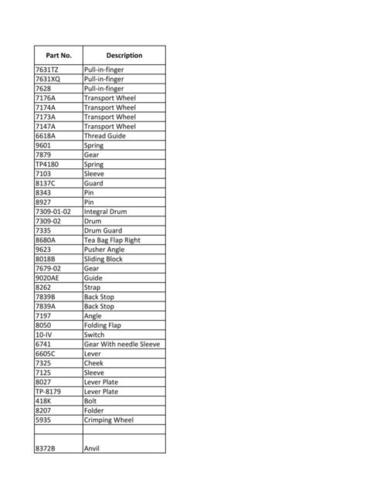

The Bushing (Part No. 1666) is a high-precision support component used in Constanta teabag packing machines, designed to guide and stabilize rotating or sliding shafts while reducing friction and wear. It plays a crucial role in ensuring smooth mechanical movement and extending the service life of adjacent components.

Manufactured from durable, wear-resistant materials, the 1666 Bushing performs reliably under continuous, high-speed packaging conditions. Engineered to exact OEM specifications, it allows for easy replacement and seamless integration into existing assemblies.

This bushing is essential for maintaining operational efficiency, minimizing downtime, and supporting consistent teabag packaging quality.

Engineered for Excellence

The Constanta 1666 bushing stands out for its precision engineering, tailored to fit the stringent requirements of packaging machinery. Made from high-grade alloy steel and available in custom sizes, its built to deliver consistent performance and superior lifespan. The components polished and coated surfaces not only enhance its aesthetic appeal but also provide exceptional resistance to corrosion and wear, ensuring peace of mind for operators and manufacturers alike.

Optimized Surface Finish & Protection

A polished finish combined with advanced surface treatment gives the Constanta 1666 bushing both visual appeal and functional strength. The high-quality coating further reinforces its endurance, making it suitable for environments where wear and tear is a constant challenge. Its availability in popular shades like silver and black adds versatility to machinery design, supporting both operational and aesthetic requirements.

FAQs of Constanta 1666 Bushing:

Q: How is the Constanta 1666 bushing installed in packaging machinery?

A: The bushing is typically press-fitted or inserted into the mechanical housing of packaging equipment. Its customized sizing allows seamless installation and a snug fit, minimizing vibration and enhancing machine performance.Q: What are the benefits of the polished and coated surface finish?

A: The polished and coated surface increases the bushings resistance to corrosion, wear, and friction. This results in a longer service life, reduced maintenance needs, and improved reliability in high-demand packaging environments.Q: Where can I use the Constanta 1666 bushing?

A: This bushing is specifically engineered for packaging machinery but can be adapted to other industrial machines requiring robust, high-precision alloy steel bushings with superior surface properties.Q: What process is used to manufacture the Constanta 1666 bushing?

A: The bushing is manufactured using advanced metallurgical and precision machining techniques, followed by polishing and surface coating to ensure dimensional accuracy, durability, and optimal surface quality.Q: When should the Constanta 1666 bushing be replaced?

A: Replacement is recommended if there is noticeable wear, deformation, or performance decline. Regular inspections based on the machinerys maintenance schedule help ensure timely replacement and prevent equipment downtime.Q: How does using this alloy steel bushing benefit packaging machinery?

A: Its robust construction and protective surface treatments minimize friction and wear, extending the lifespan of moving parts and promoting smoother, more reliable operation within the machinery.Q: Is it possible to get the bushing in different colors or sizes?

A: Yes, Constanta 1666 bushings are available in silver and black and can be produced in customized sizes to match specific equipment requirements.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

Send Email

Send Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें