Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

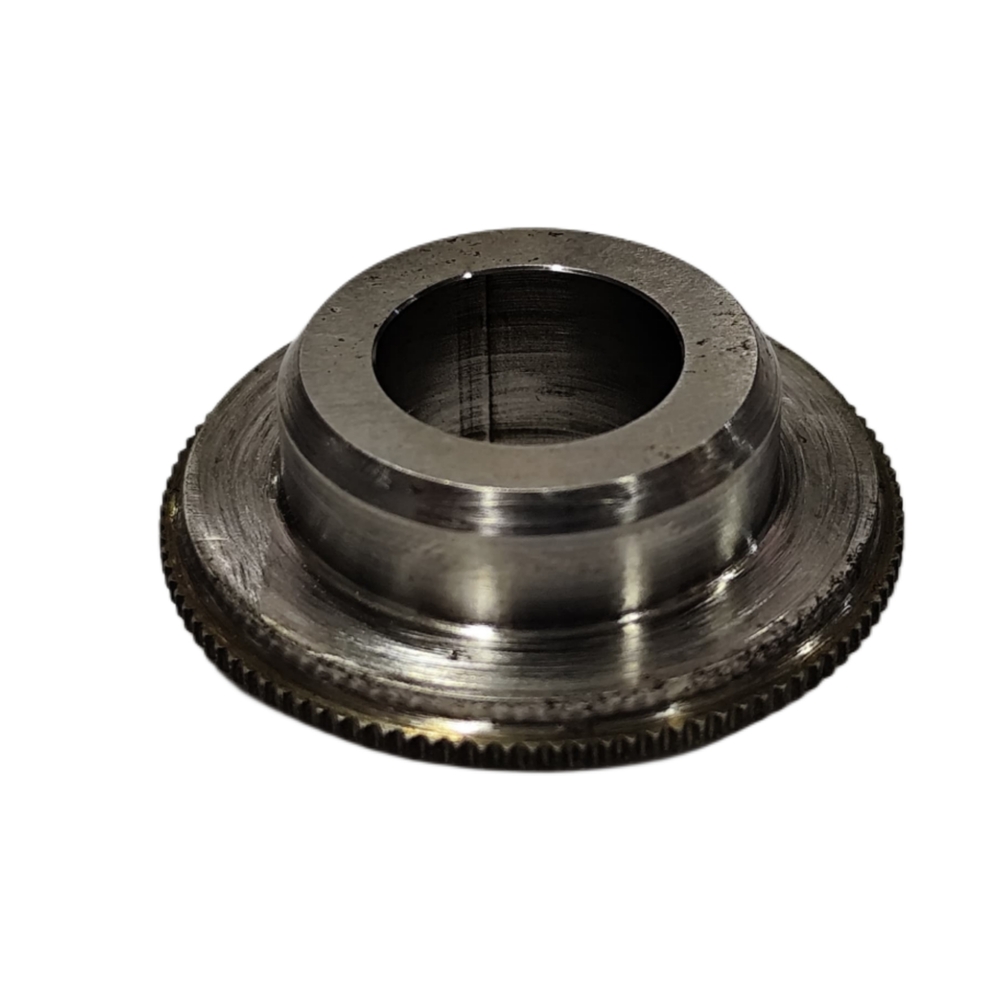

Constanta 729B IV Crimping Wheel

Product Details:

- Features High Surface Hardness, Precision Groove Profile, Long Service Life, Consistent Crimp Quality

- Size Customized

- Surface Finish Polished

- Usage & Applications Used in IV Set Manufacturing to Crimp Tubes, Cannulae, or Connectors Accurately and Securely

- Product Type Machine Spare Part

- Material Alloy

- Technology CNC

- Click to View more

X

Constanta 729B IV Crimping Wheel Price And Quantity

- 100 Piece

Constanta 729B IV Crimping Wheel Product Specifications

- Polished

- Used in IV Set Manufacturing to Crimp Tubes, Cannulae, or Connectors Accurately and Securely

- Alloy

- High Surface Hardness, Precision Groove Profile, Long Service Life, Consistent Crimp Quality

- Customized

- CNC

- Machine Spare Part

Product Description

The Crimping Wheel (Part No. 729B IV) is a precision-crafted component used in Constanta teabag packing machines, engineered to form tight, uniform crimps on the teabag edges during the sealing process. It ensures proper closure, product integrity, and consistent appearance in every teabag produced.

Made from high-strength, wear-resistant materials, the 729B IV Crimping Wheel is built for durability under continuous, high-speed operation. Its OEM-compliant dimensions ensure flawless compatibility and easy installation with minimal downtime.

Essential for maintaining sealing accuracy and machine efficiency, this crimping wheel is a key part of any maintenance or replacement cycle in tea packaging operations.

Precision Crimping for Critical Components

The Constanta 729B IV Crimping Wheel is crafted for tasks demanding utmost accuracy. Applied during IV set manufacturing, it ensures secure and leak-proof connections for tubes and cannulae. Its CNC technology delivers consistently precise groove profiles, reducing error rates and supporting high-quality manufacturing standards in medical device production.

Engineered for Consistency and Longevity

With a high surface hardness and polished finish, this alloy crimping wheel resists wear and maintains its profile over extended use. Its design emphasizes long service life and minimizes downtime for replacements, making it ideal for high-volume production environments. Each wheel is customized to client specifications for optimal fit and performance.

FAQs of Constanta 729B IV Crimping Wheel:

Q: How is the Constanta 729B IV Crimping Wheel utilized in IV set manufacturing?

A: The Constanta 729B IV Crimping Wheel is used to securely crimp tubes, cannulae, or connectors during the assembly of IV sets, ensuring tight, leak-free joints that are essential for medical safety and performance.Q: What makes the Constanta 729B suitable for medical applications?

A: Its precision groove profile, consistent crimp quality, and high surface hardness cater specifically to medical standards, providing reliable performance in critical healthcare device production.Q: When should I consider customizing the crimping wheel size?

A: Customization is recommended when manufacturing IV sets with unique connector or tube dimensions. We tailor the size to meet your specific equipment or production requirements, ensuring precise crimping results.Q: Where is the Constanta 729B IV Crimping Wheel manufactured and exported from?

A: This product is manufactured and exported from India by an experienced supplier specializing in high-quality crimping wheels for the medical industry.Q: What is the process technology behind this crimping wheel?

A: The Constanta 729B utilizes state-of-the-art CNC machining technology, delivering exceptional accuracy and surface finish for each wheel, which is then polished and quality-checked before dispatch.Q: What are the key benefits of using the Constanta 729B in your production line?

A: Key benefits include precise, secure crimps, extended service life, minimal maintenance due to high surface hardness, and enhanced consistency across every manufactured IV set.Q: How does the surface finish contribute to performance?

A: The polished surface reduces friction and material buildup, resulting in cleaner crimps and prolonging the operational lifespan of the crimping wheel.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free