Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

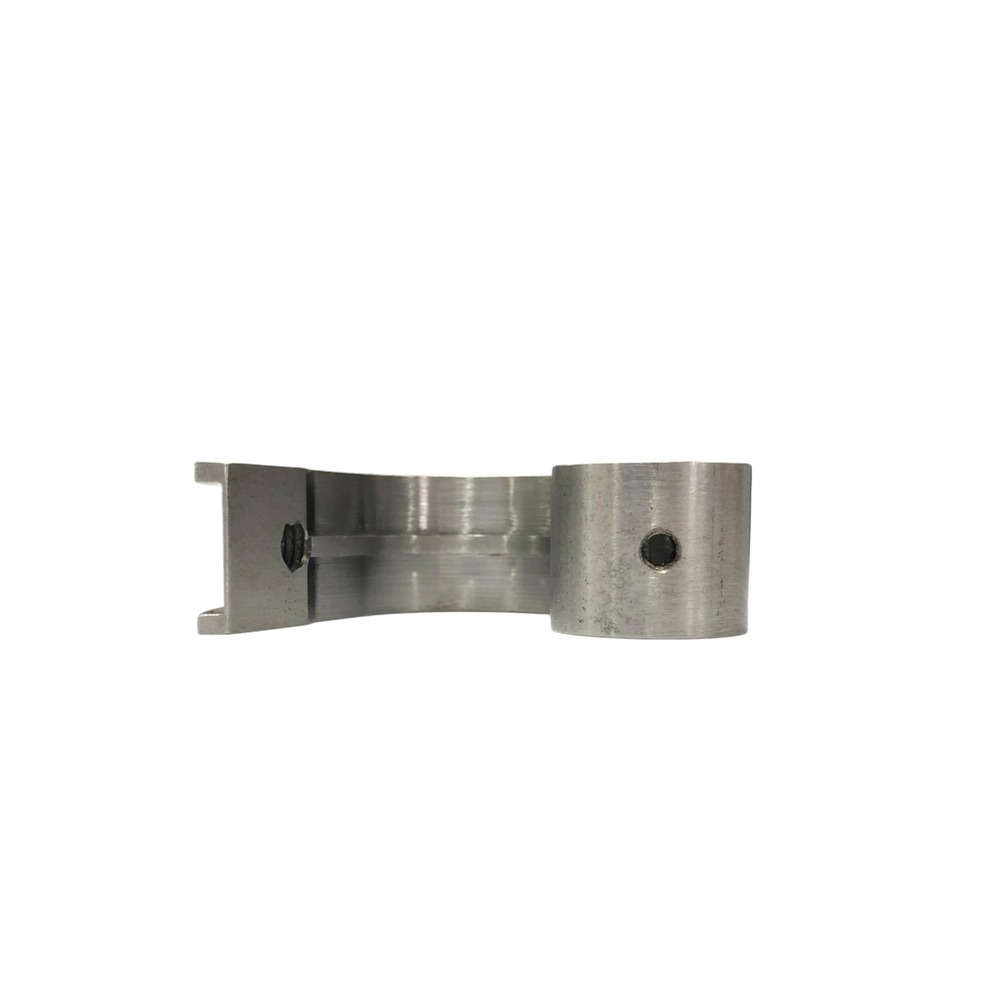

Constanta 234 I-V Lever

Product Details:

- Size Standard

- Shape Ergonomic lever shape

- Capacity Designed for rugged frequent use

- Diameter Lever handle approx. 22 mm

- Surface Finish Polished

- Drive Type Manual lever

- Usage & Applications Industrial machinery control, mechanical linkages, and actuation systems

- Click to View more

Constanta 234 I-V Lever Price And Quantity

- 100 Piece

- 1000 INR/Piece

- 100.00 - 1000.00 INR/Piece

Constanta 234 I-V Lever Product Specifications

- Lever handle approx. 22 mm

- Not Applicable (Manual)

- High-Grade Metal (Alloy Steel)

- Silent operation

- Polished

- Heavy-duty construction, Anti-slip handle, Corrosion-resistant, Easy installation

- Precision Machined Lever Assembly

- Grease groove provided

- Suitable for industrial applications

- Manual lever

- Industrial machinery control, mechanical linkages, and actuation systems

- Standard

- Silver & Black

- Anti-corrosion plating

- 230 mm x 75 mm x 30 mm (approx.)

- Approx. 0.65 kg

- Manual

- Ergonomic lever shape

- Designed for rugged frequent use

- Lever (Model 234 I-V)

Product Description

The Lever (Part No. 234 I-V) is a crucial mechanical component used in Constanta teabag packing machines, responsible for precise mechanical actuation and movement control during the teabag formation process. It transmits motion between internal mechanisms, ensuring coordinated and reliable operations.

Manufactured from high-strength, industrial-grade materials, this lever is designed to withstand repetitive mechanical stress in continuous production environments. Its OEM-specific dimensions and tolerances ensure perfect compatibility with original Constanta setups, simplifying installation and minimizing machine downtime.

The 234 I-V Lever contributes directly to the machineas efficiency, playing a vital role in timing, motion transfer, and seamless synchronization of components. A worn or misaligned lever can lead to production inconsistencies a replacing it with a high-quality part ensures long-term performance stability.

a OEM-Compatible Design

a Ensures Smooth Motion Transfer

a Built for Durability & Precision

a Reduces Operational Downtime

Superior Ergonomics and Grip

The rubber-coated handle is designed to offer a firm, anti-slip grip, making operator control safe and reliable even with frequent use. Its ergonomic shape minimizes hand fatigue, supporting long work periods in industrial settings.

Exceptional Durability and Construction

Constructed from high-grade alloy steel and treated with anti-corrosion plating, the Constanta 234 I-V lever stands up to harsh environments. Rugged design and polished finish ensure it remains resistant to wear and tear, making it suitable for heavy-duty applications.

Precision Engineering for Quiet, Reliable Operation

Precision machining and the inclusion of a grease groove in the assembly allow for smooth action and silent operation, reducing maintenance needs and supporting consistent performance in demanding mechanical linkages.

FAQ's of Constanta 234 I-V Lever:

Q: How is the Constanta 234 I-V Lever installed on machinery?

A: The lever utilizes a through-bolt mounting system, allowing for secure attachment to compatible mechanical setups and OEM machinery. Installation is straightforward, typically requiring standard tools.Q: What are the primary benefits of the rubber-coated handle material?

A: The rubber-coated handle enhances grip and comfort, preventing slipping during operation and reducing operator fatigue, especially under frequent or prolonged use.Q: When should the handle or bushing components be replaced?

A: Replaceable components like the handle and bushing should be inspected during routine maintenance. Replacement is recommended if significant wear, grip loss, or mechanical play is observed.Q: Where can the Constanta 234 I-V Lever be used?

A: This lever is ideal for installation in industrial machinery, mechanical control linkages, and actuation systems, particularly in environments where manual operation and reliability are vital.Q: What process ensures the lever's durability against corrosion?

A: The lever undergoes anti-corrosion surface treatment and precision machining, which help protect the high-grade alloy steel from rust and environmental damage.Q: How does the built-in lubricating system contribute to product longevity?

A: A dedicated grease groove ensures consistent lubrication of internal moving parts, promoting smooth, quiet operation and reducing long-term wear.Q: What advantages does the Constanta 234 I-V Lever offer in terms of safety and standards?

A: It is manufactured in compliance with recognized industrial safety standards, ensuring reliable performance and safe operation in high-demand scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free