Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Have a query ?

08045476491

Have a query ?

- Home Page

- Company Profile

-

Our Products

- IMA C24/C27/C28 Spare Parts

- IMA C24 TC1120335 Spring

- IMA C27 Needle holder

- IMA C27 Crochet

- IMA C27 Gripper (Gripper)

- IMA C27 TC1310022 Tag Punching Side Bit

- IMA C27 TC1310014 Plate for knife

- IMA C24 TC1120336 Spring

- IMA C24 TC1040014 Carrugation roller

- IMA C24 TC1120288 Thread puller

- IMA C24 TC1480048 Bracket for fastening the package volume adjustment fork

- IMA C27 TC1120342 Gripper

- IMA C27 TC1120326 Gripper

- IMA C27 TC1C80003 & TC1C80004 Gripper

- IMA C27 TH3500005 Needle Guide

- IMA C24 Spare Parts List

- IMA C24 TC1120320 Left Hook Mounting Bracket

- IMA C27 TC1310010 Blade (Counteracting)

- IMA C24 TC1050009 Filter Paper Moving Knife

- IMA C24 TC1B80047 TC1B80062 Package Holder

- IMA C24 TC1120354 Thread Puller

- IMA C24 TC1120338 Left Hand Crochet

- IMA C27 TC1630010 Middle punch knife

- IMA C24 TC1050006 Filter Paper Fixed Knife

- IMA C24 TH3120200 Loop needle (Right)

- IMA C24 TC1120158 Right Hand Needle

- IMA C24 TC1150111 Spring Plate

- IMA C24 TC1040030 3rd fold plate

- IMA C27 Folder Guide

- IMA C27 Machine Gripper

- IMA C27 Needle

- IMA C27 Tag Punch

- IMA C28 TC1120266 Pressure Pad

- IMA C27 TC1120158 Needle

- IMA C24 TC1120289 Thread tension axis

- IMA C24 TH3100007 Lower front introducer

- IMA C24 TC1410009 Fixed Gripper

- IMA C24 TH3100006 Bottom shaper of the package rear lower

- IMA C24 TC1410012 Movable Gripper

- IMA C24 TC1120339 Left Hand Needle

- IMA C27 TC1120293 Right hand crochet

- IMA C21/C23 Spare Parts

- IMA C23 C23080047 Thrust ring for the bracket of the external grips of the telescope

- IMA C21 C21F00063 Gripper

- IMA C21 C20060345 Tag Fixed Knife

- IMA C21 C20080028 Shifter Pin

- IMA C21 C20100048 Lever

- IMA C21 C20630022 Heater Holding Plug

- IMA C23 C23060427 Cover

- IMA C21 Helical Gear

- IMA C23 Thread Puller

- IMA C21 Thread cutting fixed knife

- IMA C21 Spark Gear

- IMA C21 Thread cutter

- IMA C21 C201600016 Fixed Thread Knife

- IMA C23 C23080022 Front envelope transfer grip support

- IMA C23 C20070117 Staple blade backing

- IMA C23 C21030064 Filter bag roller

- IMA C21 C20630021 Heater Holding Plug

- IMA C23 C23F00204 12 Hours Busket

- IMA C23 C23060166 Tunne (Bronze)

- IMA C23 C23080269 Bearing Cup of Inner Grip Axis

- IMA C23 C23030159 Carriage

- IMA C23 C239A0037 Lever Traction Grip 12 O'Clock Down

- IMA C21 Heat Sealing Jaw

- IMA C23 C23070018 Cover of the stapler with groove for the label

- IMA C23 C233C0008 Grippers Head

- IMA C23 C239A0054 Package Grip Axis

- Maisa Finger Tea Bag Machine Spare Part

- Maisa Filter Paper Cutter

- Tag Cutter

- IMA C21 C20060304 Thread moving knife

- IMA C21 C20060191 Tag moving knife

- IMA C23 C23060352 Lable grip of movable

- IMA C23 C21960039 Hopper

- IMA C23 C239A0055 Axis of opening of the package transfer gripper

- IMA C23 C23080126 Envelope knife rear guide

- IMA C23 C20070058 Stapler rachet wheel

- IMA C23 C20070121-01L Ear pull left hand thread

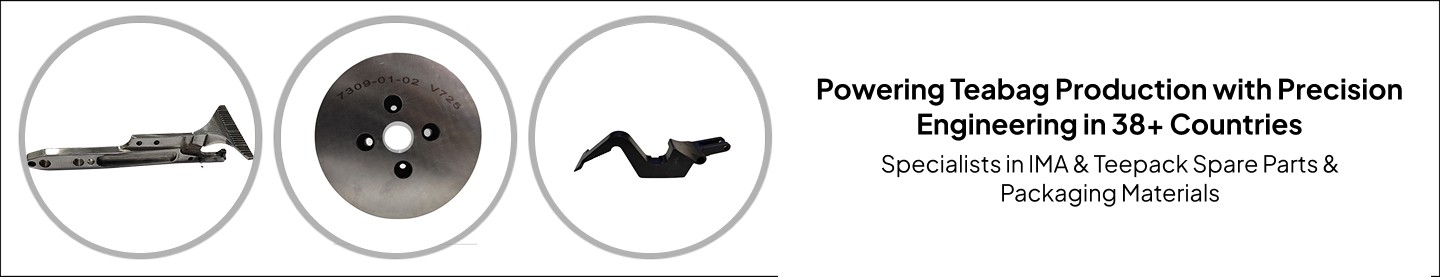

- Teepack Perfecta/ Constanta Spare Parts

- Constanta 430 Separator

- Perfecta 7309-01-02 Transport Wheel

- Constanta 1666 Bushing

- Constanta 1675 Thread Holder

- Constanta 1827 Roll

- Constanta 3669 II-V Finger

- Constanta 3730 Bushing

- Constanta 4180 Spring

- Perfecta 2044 Knife

- Perfecta 7174 AK Transport Wheel

- Perfecta 7176 AK Transport Wheel

- Perfecta 8508 Lower Thread Cutter

- Constanta 1665 Bolt

- Perfecta 8514B Upper Thread Cutter

- Constanta 1636 Break Spring

- Perfecta 8939BE Anvil

- Perfecta 9040 Leaf Spring

- Perfecta 9713A Claw Holder Right Hand

- Constanta 355B Fold Pusher

- Constanta 407 Bushing

- Constanta 4669 Bushing

- Constanta 122 IV Folder Spring

- Constanta 263 I-V Retaining Spring

- Constanta 497 Stripper

- Constanta 260 I-V Bushing

- Constanta 450B Insert

- Constanta 1669 Clamping Bow

- Constanta Guide

- Perfecta 8244 Guide

- Constanta 552 Stop

- Constanta 729B IV Crimping Wheel

- Constanta 491 Break Spring

- Constanta 1504 I-V Filter Paper Upper Knife

- Constanta 467 IV Break

- Constanta 440 Bushing

- Constanta 1465 Angle

- Constanta 959 II-V Spring

- Constanta 729A IV Crimping Wheel

- Constanta 1511 Coller Bush

- Constanta 727 Bearing

- Constanta 415A Guide Plate

- Constanta 425B Cutting & Bending Die

- Constanta 219A Block

- Constanta 271 I-V Thread Bolt

- Constanta 401B Anvil Plate

- Constanta 255 IV Guide ring

- Constanta 415B Guide Plate

- Constanta 2316 Stop angle

- Perfecta 7631 TZ Pull in Finger

- Perfecta 7628 Pull in finger

- Constanta 1470 Switch Latch

- Constanta 1659B Bolt

- Perfecta 8088 Ring

- Constanta 425A Cutting & Bending Die

- Perfecta 6618 A Thread Cutter

- Costanta 219B Block

- Constanta 2310 Bushing

- Constanta Tucker

- Constanta Aluminum wire cutter

- Constanta W Folder

- Constanta Thread cutter

- Constanta Anvil

- Constanta Bag Gripper

- Perfecta Teabag Packaging Machine Spares

- Constanta Driver

- Constanta 483 Thread Cutter

- Perfecta 6605 C Lever

- Constanta 553 Stop peg

- Constanta 429 Driver

- Constanta 401A Anvil Plate

- Constanta 597 Knife holder

- Constanta 419 Guide Block

- Constanta 416 Bending Matrix

- Constanta 964 II IVK Pusher CPL

- Constanta 729C IV Crimping wheel

- Constanta 1505 I-V Filter paper lower knife

- Constanta 652 Bunny spring

- Perfecta 8680 Flap modified

- Perfecta 9712A Claw holder left hand

- Constanta 234 I-V Lever

- Constanta 235 II-V Lever

- Constanta 324 I-V Finger

- Teabag Packaging Materials

- Contract Packaging of Teabags

- IMA C24/C27/C28 Spare Parts

- Contact Us

Contact Us

- 57 Shakespeare Sarani, Ground Floor Kolkata - 700017, West Bengal, India

- Phone : 08045476491

VEDIKA MACHINERY PVT. LTD.

GST : 19AADCV0908N1ZZ

- Mr. Srikumar Bhootra (Managing Director)

- Mobile : 08045476491

- Mr Vedant Bhootra (Executive Director)

- Mobile : 08045476491

-

Accepts only Export inquiries

kspares@live.com

Accepts only Export inquiries

kspares@live.com

Products

VEDIKA MACHINERY PRIVATE LIMITED

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.

Send Email

Send Email Send Inquiry

Send Inquiry Send SMS

Send SMS