Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM Mon - Sat : 9.00 AM - 6.00 PM

Mon - Sat : 9.00 AM - 6.00 PM

Perfecta 6618 A Thread Cutter

Product Details:

- Usage & Applications Industrial

- Product Type Machine Spare Part

- Material Mild Steel

- Surface Treatment Painted

- Color Gray

- Warranty 1 Year

- Click to View more

Perfecta 6618 A Thread Cutter Price And Quantity

- 1 Piece

Perfecta 6618 A Thread Cutter Product Specifications

- 1 Year

- Machine Spare Part

- Gray

- Industrial

- Mild Steel

- Painted

Perfecta 6618 A Thread Cutter Trade Information

- 100 Piece Per Month

- 30 Days

- Standard

Product Description

Thread Cutter: Part No - 6618 A

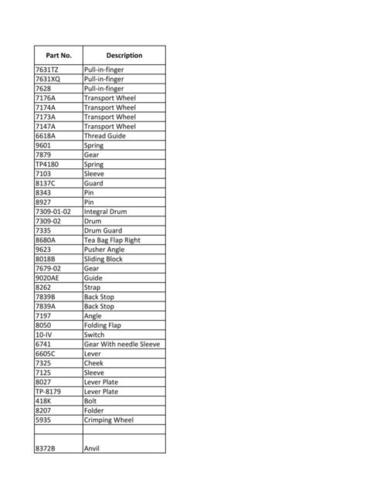

Teepack Perfecta Spare Parts

The Teepack Perfecta is a high-speed, staple-lessteabag packaging machine known for precision, flexibility, and integrationcapabilities. Designed for modern production lines, it remains one of the mostwidely used machines in the teabag industry.

At Vedika Machinery, we provide spare parts for over 105 Perfectaunits globally, with a growing portfolio of reverse-engineered criticalspares developed from client-supplied samples and drawings.

Our current offerings include:

- Tag feeding and cutting units

- String handling modules

- Heat sealing tools and jaws

- Cam, linkage, and gear assemblies

- Motion and drive transmission elements

Each part is manufactured using high-performance imported alloys andtested for compatibility with running Perfecta machines.

Get OEM-grade parts for Perfecta with faster lead times andsignificant cost savings.

Premium Industrial Build

Constructed from high-quality mild steel, the Perfecta 6618 A Thread Cutter is engineered to withstand demanding industrial settings. The painted gray finish offers additional protection from corrosion, making it ideal for rigorous daily use in manufacturing environments.

Versatile Thread Cutting Applications

This thread cutter is versatile and suitable for a range of threading needs in industrial workshops. From precision operations to high-volume tasks, it enhances efficiency and ensures clean thread finishes, contributing to optimized workflow and consistent results.

Reliable Manufacturer and Exporter

Manufactured and exported from India by a reputable company, the Perfecta 6618 A Thread Cutter comes with a 1-year warranty. Each unit undergoes stringent quality checks, ensuring international standards and reliable performance for global customers.

FAQs of Perfecta 6618 A Thread Cutter:

Q: How do I operate the Perfecta 6618 A Thread Cutter for optimal performance?

A: To achieve the best results, ensure the cutter is securely mounted and properly aligned with your workpiece. Follow the manufacturers guidelines for threading speed and apply adequate lubrication to reduce wear and tear during cutting operations.Q: What materials can the Perfecta 6618 A Thread Cutter efficiently handle?

A: This thread cutter is constructed from mild steel and is specifically designed to cut threads on various industrial materials, especially mild steel and similar metals, delivering consistent and accurate thread profiles.Q: When should I perform maintenance on the Perfecta 6618 A Thread Cutter?

A: Regular maintenance is recommended after extensive use or at least every few months. Inspect the cutter for signs of wear, clean thoroughly, and check for any paint chipping or surface corrosion to ensure optimal longevity.Q: Where is the Perfecta 6618 A Thread Cutter manufactured?

A: The product is manufactured in India, adhering to strict industrial standards, and is exported to international markets by a trusted exporter and manufacturer.Q: What is the process for claiming the 1-year warranty?

A: Should your thread cutter develop any manufacturing defects within one year of purchase, contact the supplier or manufacturer with your purchase receipt and product details to initiate a warranty claim.Q: How is the surface of the Perfecta 6618 A Thread Cutter treated, and what are the benefits?

A: It features a painted surface treatment in gray, delivering added protection against corrosion, improved durability, and a professional appearance suitable for industrial settings.Q: What are the main benefits of using the Perfecta 6618 A Thread Cutter in industrial applications?

A: The tool offers robust construction, efficient thread cutting, and reliable performance, which increases productivity and minimizes downtime. Its industrial-grade build ensures long service life and consistent results in demanding thread cutting tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS